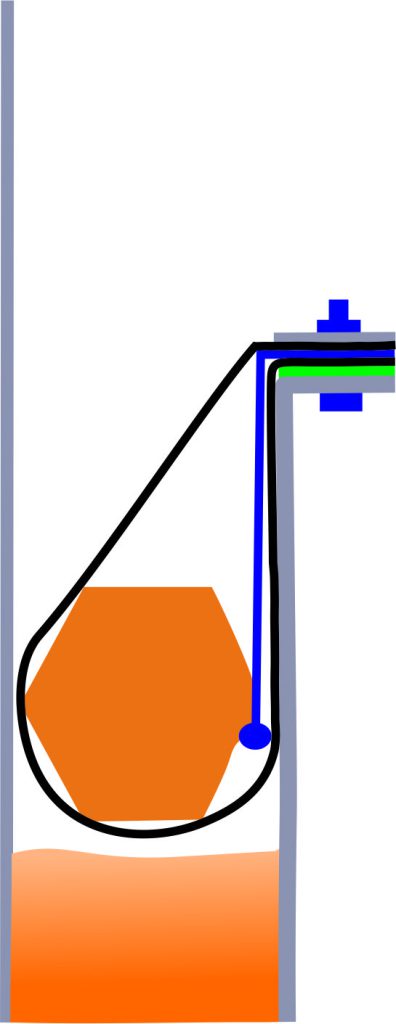

Vapour Mounted Primary Foam Seal

In terms of lowering emissions, the primary foam seal is the most effective primary tank seal. The design is built on a polymer fabric reinforced cover that is kept down by steel hold-down plates or hold-down bars around a springy polyurethane foam core. Since the seal is very flexible, it contacts the tank shell across a large region, guaranteeing excellent rim space vapour tightness. Each primary foam seal will be tailored and manufactured to suit the tank, guaranteeing that the seal can handle both the product stored as well as the tank’s unique dimensions and design factors. Primary foam seals are available in both vapour and liquid mounting and are suitable for a wide variety of applications for EFR and IFR tanks

Key Features

- Excellent vapour tightness, resulting in maximum emission reduction in accordance with the regulations.

- Stops a lot of rainwater from entering into the product.

- All stored products, including 100% aromatics, are compatible.

- Comes in a variety of material combinations Stainless steel, coated steel with a polyurethane casing, or a rubber casing are also all available.

- Suitable with both vertical and horizontal roof rim angles, without no rim modifications required

- Tailored to each specific tank

- Easy to Install

- API, EN, BREF IPPC, EPA, ATEX, NFPA, as well as other international (environmental) standards all are fulfilled

- It can be used with any secondary seal design.

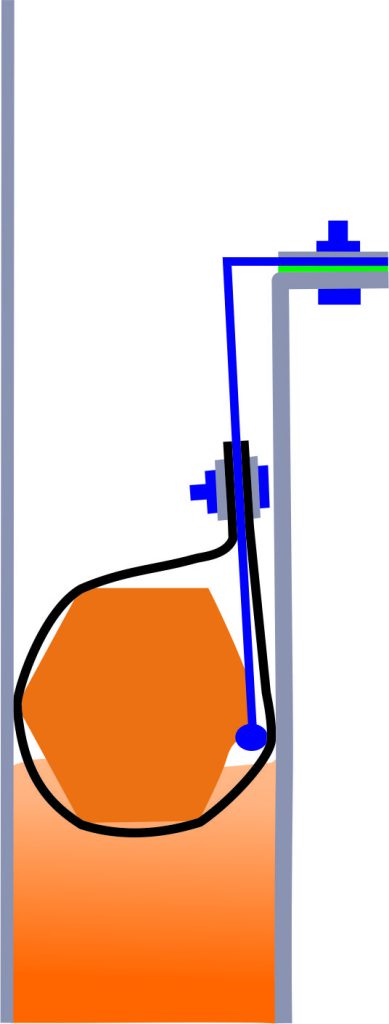

Liquid Mounted Primary Foam

When it comes to reducing emissions, the liquid-mounted foam seal is one of the most effective primary tank seals. The robust polyurethane foam core of this sealing system provides a continuous sealing force regardless of the geometry of the tank shell. Maximum sealing pressure against the tank shell is maintained by a hold-down plate or hold-down bar, along with reinforced polymer fabric. Due to the obvious large contact area, this seal is extremely tight. The liquid-mounted foam seal avoids vapour condensation completely, but the immediate contact between the liquid and the seal envelope enhances the material requirements considerably.

Key Features

- Excellent vapour tightness, resulting in maximum emission reduction in accordance with the regulations.

- Stops a lot of rainwater from entering into the product.

- All stored products, including 100% aromatics, are compatible.

- Comes in a variety of material combinations Stainless steel, coated steel with a polyurethane casing, or a rubber casing are also all available.

- Suitable with both vertical and horizontal roof rim angles, without no rim modifications required

- Tailored to each specific tank

- Easy to Install

- API, EN, BREF IPPC, EPA, ATEX, NFPA, as well as other international (environmental) standards all are fulfilled.

- It can be used with any secondary seal design.

We are one of the leading manufacturers, suppliers, and Exporter of Primary Foam Seal based in M.I.D.C. Anandnagar, Ambernath, Mumbai, India.